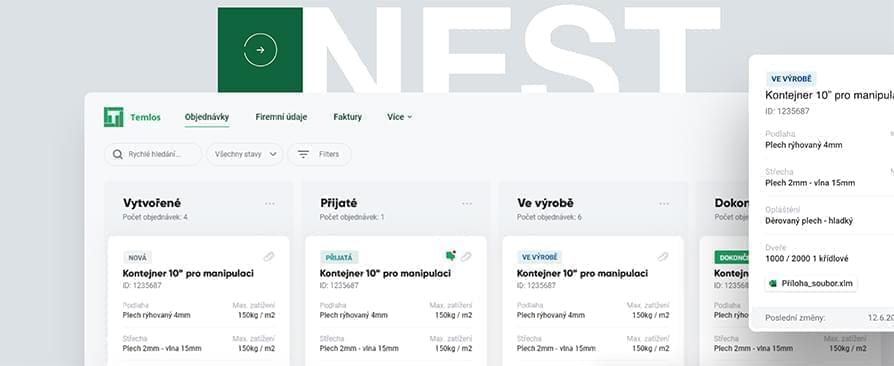

Project management

Important role in our business is to consult and find a solution to the many technical questions. Our highly qualified team is able to prepare a unique 3D model in specialized programme as AUTOCAD based on individual needs of the customer. Individually prepared offer will be made as a part of the process. By the time the individual offer is confirmed, our manufacturing team takes over to begin the work on your project.

When needed, we are offering to ensure the documentation of structural analysis and statics confirmation. All the certificates are pursuant to EU legislation.

Technical description of container Temlos

Based on our experience we often face that the installed technology requires different parameters than standardized dimension. In that case we are able to customize the framework individually for each customer. The biggest containers ever made were maximum 22000mm long, 4500mm wide and 4500mm high.

Base framework

The framework mainly depends on the right choice of a constructing material. For the base framework we use standard rolled and bent profiles. The material has S235J and S355J grade.

Floor

- The floor construction is tailored to the usage conditions.

- The floor construction is made from the floor framework with the diagonal elements covered by the sheet metal. You can easily choose the flat sheet metal or riffled sheet metal with great nonskid feature.

- Floor’s weight load in standard version of 500 kg/m2. Higher load upon wishes available.

- The floor shaped as a tub tightly sealed to the floor sheet metal.

- High advantage of the steel floor is a possibility to attach additional elements in order to hold installed technology.

- Heat and acoustic isolation for the floor is ensured by using mineral wool or styrodur. Bottom coverage is made of galvanized metal sheet or black metal sheet. The metal sheet could be rivetted or welded right to the base framework. Lower floor structure treated and covered with bitumen coat.

- For the switchboard specially made containers we use floors with detachable sheets covered with nonskid antistatic rubber.

- In the containers used for waste disposal from ČOV is implemented self-levelling cast floor 2mm thick.

Roof

- The roof construction can be customized to individual needs of the customer. The roof is usually made from 2mm trapezoidal sheet metal, wool height is 15mm. To assure better outflow of the rain water, the middle part of the roof is along sides slightly elevated.

- The dimensions of the roof can be adapted upon customer’s wishes. Strengthening is made by adding additional profiles.

- The roof can have different technological arrangements such slots or detachable covers.

- Weight roof load 150 kg/ m2. The roof is walkable.

- We also offer additional equipment such as ladders, railing, platforms and others. Upon request the roof is made with nonskid surface.

Sheathing

- Outer sheathing is made by trapezoidal profile, wool height 35mm or made with strengthened flat sheet metal.

- Standard version of metal sheet trapezoidal sheathing for the container is 1,5 mm thick.

Isolation

- Heat and acoustic isolation for roof and walls is ensured by using mineral wool or styrodur.

- Mineral wool is characterized by great heat isolating qualities, acoustic qualities and properties of fire protection that strengthens the framework passive safety for all our containers. In addition wool offers low thermal conductivity and anti-absorbing power. We use materials of fire grade A1 by EN 13 162.

- Inner wall coverage and roof coverage is made with perforated galvanized sheets in optional flat sheets, case shaped, flat galvanized sheets, PE plates, laminated or gypsum fiberboards.

Doors, gates and assembly slots

- We use doors made be Teckentrup company. Wide size range offers to fulfill the expectations of all the customers. Door systems are equipped with locking mechanisms and door closing mechanism. Upon request we are able to install anti-panic locking mechanism that helps to escape from closed space. Single-winged or double-winged doors are suitable for transverse as well longitudinal side of the container. Fire resistance door could be used as well. All doors are certified.

- Double-winged container gate comes with galvanized steel hinges that helps to avoid corrosion. The amount of used hinges is based on the dimension of the gate. The gate is lockable with outer bar-closing mechanism. Isolation is made by rubber sealing.

Technological slots/gaps

- In case of specified container solutions for specialized usage are technological slots essential element of sheathing, floor or even roof.

- Wide range of sizes and shapes of technological slots satisfies needs of each customer. Manufactured with frames, cover grid, flange or simple cover. As well window systems are available.

- Slots for air supply and exhaustion could be covered by grids to ensure the wind protection. Safety net included.

- Front side of the container with tailgate helps to facilitate comfortable loading and unloading of the technology.

Surfacing modification

- The right preparation for application of high quality coating is essential. For long-lasting paint we clean and coarsen the surface.

- All our manufactured products are spurted before paint application.

- Standardly is used coating system C3. Other based upon customer’s request.

- Standardly is used color toning in the range RAL and Pantone.

Manipulation

- For manipulation with containers certified container corners or hanging hooks are used.

- For manipulation with fork-lift truck floor pockets in the container can be used.

- In special cases we offer the availability of adding foldable supporting arms pursuant EN284:2006.

- Manipulation points can be used as well for lids or detachable front panels.